Linville WTP Design & Construct

Completion Date: April 2020

Practical Engineering delivers new Water Treatment Plant for Linville

The regional Queensland township of Linville is now receiving treated water from the new Linville Water Treatment Plant, commissioned in April 2020. Practical Engineering Australia (PEA) were engaged by Seqwater for the design and construction of the new $3 million plant. The Linville WTP is in the North Somerset Region, 40km North-West of Kilcoy.

The WTP services approximately 80 connections through infrastructure owned and operated by Queensland Urban Utilities. The existing WTP was taken offline following damage to the bore infrastructure during flooding in January 2013 and has not been reinstated since. As Linville is not connected to the water grid, the supply of safe drinking water since the plant was shut down has been maintained by using water tankers to fill the two onsite storage tanks which feed the town reservoir.

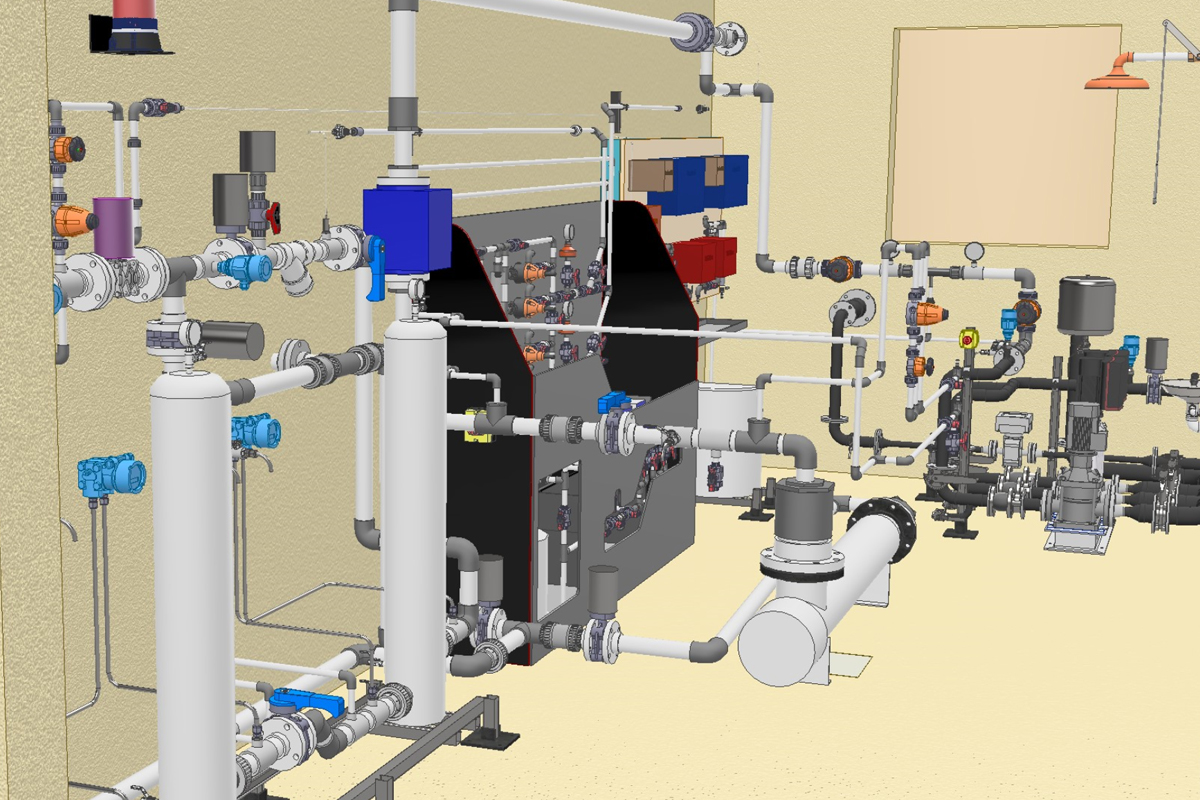

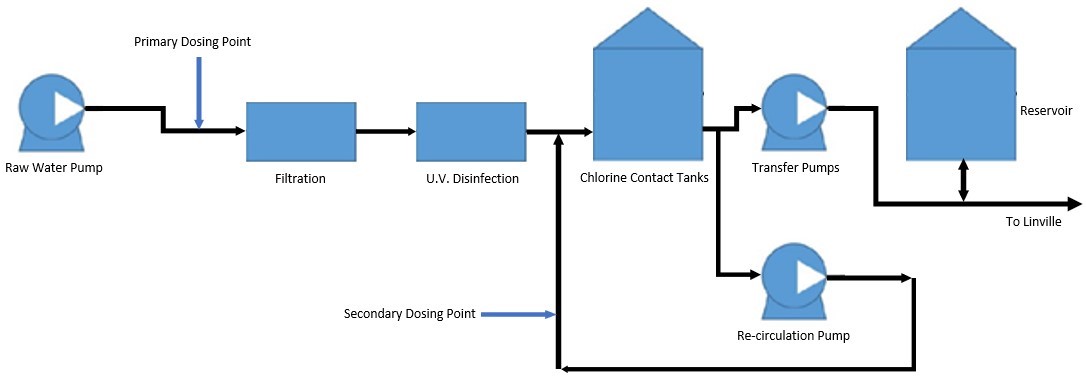

The WTP upgrade was commenced in September 2019 with the installation of a temporary pumping system to maintain water supply to the town during construction. The existing building was then demolished, before construction commenced and was completed in February 2020. Commissioning commenced in March and was completed in April 2020. The new plant is fully automated and consists of a bore water supply, in-line 2 stage cartridge filtration, UV disinfection and sodium hypochlorite dosing. A new submersible bore pump supplies raw water at up to 6m3/hr to the validated cartridge filtration system. Sodium hypochlorite is dosed upstream of the filters, inhibiting biofilm formation on the filters and iron/manganese oxidation.

The filtered water then passes through a UV disinfection unit before entering two on site chlorine contact tanks. A recirculation pump operates constantly, providing online chlorine, pH and turbidity readings and facilitating a secondary sodium hypochlorite dosing point. Treated water is then pumped from the contact tanks via a pair of variable speed pumps into the rising main to Linville and to the local storage reservoir. The Linville plant is formally rated at 120m3/day, operating at 6m3/hr for 20 hours. The figure below shows an overview of the process system.

Process and mechanical design work was completed in-house, with PEA managing all design disciplines from concept through to detailed design. As the Principal Contractor, PEA managed and operated the regional construction site. Works on site included demolition of the existing asbestos structure, extensive groundworks and foundations as well as installation and commissioning of the state-of-the-art automated plant.

PEA personnel and contractors supported the local Somerset community throughout construction and commissioning by using local accommodation and associated industries. An estimated total of 5,500 personnel-hours was spent on the construction site alone, with many additional hours logged prior to mobilising to site. Most key contractors were lodged in the local town of Kilcoy, using the local town conveniences throughout the construction project.