AS4100 Steel Structures

When you look at AS4100 in relation to engineering applications for steel structures, you will find bridges, buildings, industrial facilities, mezzanine floors, crane runways and portal frames are most common. At Practical, we start by thinking of the AS4100 as guidance and minimum safety standards for structural engineers. How we should analyse the steel structures and how steel beams and connections should be designed to ensure their safety and reliability.

Three methods of analysis are permitted by AS4100 for the design of steel structures:

AS4100 Analysis Types

1. Linear Static

This is the most basic form of analysis but is in fact regularly the first checked in the early stages of engineering assessment where it can allow for rapid feedback before more in-depth analysis is required, providing economies on time for clients. The analysis is considered static in time and the displacement response of the object is linear with respect to the load applied. The linear static model does not consider how stiffness and loads change due to eccentricity of displaced structures. AS 4100 provides methods for approximating these non-linear effects by amplifying loads in the linear static analysis to account to eccentricity.

2. Non-linear Static

This method more accurately captures real changes in the load-response behaviour by iteratively solving and updating the problem until convergence, and additionally by breaking application of loads into multiple steps. Considers the ultimate load that can be applied before failure occurs to the structure. The non-linear behaviour considered includes:

• Geometric non-linearity, which accounts for changes in the structure’s stiffness that result from displacement and the moment effects of load displacement

• Contact non-linearity, which occurs where local stiffness changes rapidly in response to contact or partial contact between surfaces

• Optionally can consider material yielding behaviour

This method is commonly applied in conjunction with linear static methods for further analysis of changes in load and time.

The video shows both the Linear and Non-Linear methods of analysis consider majority of steelwork to remain in the material’s linear portion of its stress strain curve.

The third method, Plastic Analysis, differs from this approach and permits under certain conditions the stresses within members to approach and exceed the yield stress limit.

3. Plastic Analysis

The primary benefit is the ability to redistribute bending moment along a beam until a complete hinge mechanism has formed.

• This method is computationally more difficult and less often utilised as the methods above cover the majority of projects assessed.

• AS 4100 places certain restrictions on member slenderness to ensure that beams can achieve their full section capacity against the economics of reducing member size.

Earthquakes

Did you know that AS4100 also covers earthquake detailing minimum requirements and assessment of steelwork for fire resistance? Even in locations across Australia, Practical is regularly engaged to ensure adherence to AS4100 even if an earthquake hasn’t happened in that location for hundreds of years.

In practice, steel structures deflect under load, including those generated by the movement of the ground. Loaded columns and other members that experience side sway deflection can subsequently experience additional loading due to the eccentricities of vertical loads induced by the deflection.

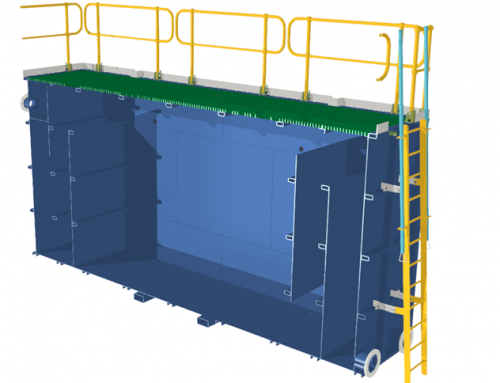

The video is a structural assessment we did of a pipe bridge considering seismic loading on the structure’s dead-load and live load. Practical use the results to identify critically loaded structural members and sway/deflection during a seismic event and ensure the underlying foundations have the capacity to support the structure.